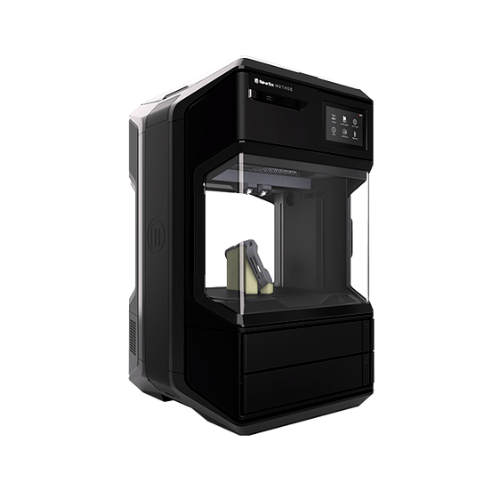

MakerBot Method X 3D Printer

The MakerBot Method X is a high performance, a tinker-free 3D printer that was designed to handle the most complex 3D printing needs. Featuring a 100°C heated chamber, The Method X is capable of printing a wide range of durable real-ABS parts and other material types right out of the box. In addition to its material capabilities, Method X also features high-quality components including dual performance extruders, precision dissolvable supports, and dry-sealed material. Method X is the perfect choice for printing manufacturing tools, end-user parts, and functional prototypes.

The MakerBot Method X is a high performance, a tinker-free 3D printer that was designed to handle the most complex 3D printing needs. Featuring a 100°C heated chamber, The Method X is capable of printing a wide range of durable real-ABS parts and other material types right out of the box. In addition to its material capabilities, Method X also features high-quality components including dual performance extruders, precision dissolvable supports, and dry-sealed material. Method X is the perfect choice for printing manufacturing tools, end-user parts, and functional prototypes.

A high-performance desktop 3d printer with industrial power

The perfect choice to handle the most complex 3D printing needs, the MakerBot Method X is a high-performance 3D printer designed to print working prototypes, manufacturing tools, fixtures and end-use parts with ease.

Features

- Dual Performance Extruders up to 300° C – Model 1XA Extruder and Support 2XA Extruder

- Thermal regulated build chamber up to 110°C

- Over 300,000 hours of reliability testing

- 21 Sensor suite – smart features for materials and performance

- Production-grade materials for advanced manufacturing

- Remote monitoring & printing

Print prototypes and functional parts

The MakerBot Method X makes the reliable and precise rapid production of 3D printed tools, parts, and custom jigs and fixtures accessible with real manufacturing grade materials.

- 3D print complex parts with ease using soluble support structures

- Replace slower, costly traditional methods with rapid prototyping

- Create end-use parts in-house

- Selected by a wide range of industries

Full active heat immersion

The circulating heated chamber maintains a stable print environment up to 110° C and provides controlled cooling of printed parts, allowing for:

- Superior Z-layer bonding

- Higher dimensional accuracy

- Better layer adhesion

- Improved part strength

- Effective reduction of first-layer warping

Optimized design for precise 3D printing

The Method X is a 3D printer built to last. The ultra-rigid metal frame running the full length of Method X’s body is designed to offset flexing, resulting in more consistent print results with better part accuracy and fewer failures.

- Over 300,000 hours of system reliability and print quality testing

- Ultra-rigid metal frame to offset flexing

- Structurally optimized

- Dry-sealed material bays

- Build volume of 152 x 190 x 196 mm / 6.0 x 7.5 x 7.75” with dual extrusion

- 190 x 190 x 196 mm / 7.5 x 7.5 x 7.75” build volume with single extrusion

Save on time and costs with sensor suite of smart features

The MakerBot Method X is equipped with a full sensor suite to maintain a consistently controlled performance, preserve the peak quality of materials, and to provide an uninterrupted manufacturing workflow. The Method X features an impressive 21 automated sensors including:

- Material Drawer:

- Temperature and Humidity control

- Material detection – remaining material, material color, material type

- Smart-Assist Material Loading

- Performance extruders:

- Temperature

- Material detection

- Encoder (Automated print jam detection)

- Printer:

- Lid and Door – open/closed status

- Temperature sensors – heated chamber

- Auto Calibration sensor

Print with manufacturing grade materials

The Method X is capable of printing real, production-grade ABS and Stratasys SR-30 soluble supports. Compared to traditional ABS filaments, the MakerBot ABS filament:

- Withstands up to 15°C higher temperatures

- Up to 26% more rigid

- Up to 12% stronger

- Achieves exceptional dimensional accuracy

- Allows for complex, durable parts

Seamless cad integration

Compatible with over 30 CAD file types, the Method X provides an impressively fast CAD-to-part workflow to optimize your rapid part production process, featuring plugins for:

- Solidworks

- Autodesk

- Fusion 360

- Inventor

See how makerbot customers are succeeding

Learn how real customers in the aerospace and automotive industries and in higher education are all succeeding with rapid prototyping and end-use part production on the Method X in the following case studies:

What materials can I print with the method x 3d printer?

The Method X comes standard with the Model 1XA Extruder and a Support 2XA Extruder. This means that you can print with several advanced materials on this machine out of the box, including:

- [NEW] ABS-R

- ABS

- ASA

- PC-ABS

- PC-ABS FR

- SR-30

- [NEW] RapidRinse

Additionally, access even more material compatibilities with 6-in-1 Modular Performance Extruders to print metals, composites, and polymers or to quickly change material groups without cross-contamination.