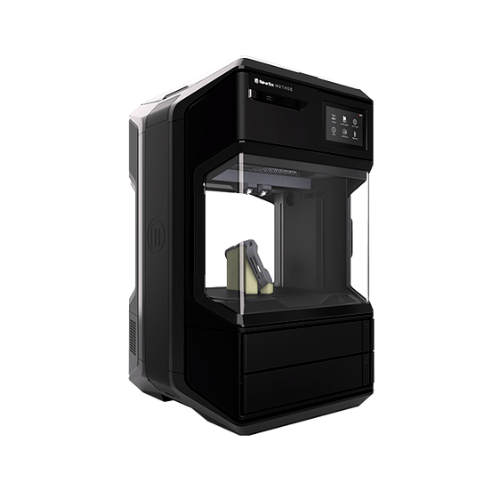

MakerBot Method 3D Printer

The MakerBot Method is a performance-grade, tinker-free 3D printer that brings industrial-grade features into the desktop 3D Printer space. Featuring high-quality components including a 60°C heated build chamber, precision dissolvable supports, dry-sealed material bays, and dual performance extruders. Method is the perfect choice for printing quick prototypes, fit tests, and concept iterations.

The MakerBot Method is a performance-grade, tinker-free 3D printer that brings industrial-grade features into the desktop 3D Printer space. Featuring high-quality components including a 60°C heated build chamber, precision dissolvable supports, dry-sealed material bays, and dual performance extruders. Method is the perfect choice for printing quick prototypes, fit tests, and concept iterations.

Method brings industrial grade features to the desktop 3D printing space

Designed to deliver uncompromised performance right out-of-the-box, the MakerBot Method is packed with features – delivering maximum innovation with minimal investment on the part of users.

Features

- Dual Performance Extruders

- Dry-sealed material bays

- 60°C circulated heated build chamber

- Wifi connectivity & 21 on-board sensors

- Remote monitoring & printing

- Seamless CAD integration with AutoDesk Fusion 360, AutoDesk Inventor, and Solidworks

- 25 compatible CAD file types

- 5” Full-color capacitive touch screen

- Over 300,000 hours of reliability testing.

Method is built to last for years to come

A structurally optimized metal frame runs the full length of the Method’s body. This ultra-rigid metal frame was designed with the sole purpose of offsetting flexing, less flexing results in more consistent prints, more accurate parts, and fewer failures overall.

Achieve uncompromised layer adhesion and part strength

Featuring a 60°C circulating heated chamber, Method allows users to control the temperature and quality of every layer. While heated build plates are effective at reducing first layer warping, the Method takes this approach one step further with full active heat immersion – providing even temperatures for the entire duration of the print job.

Smart features help to reduce cost and save time on small production manufacturing runs

The dual performance extruder system utilized by the Method, was built from the ground up with the goal of accelerating print times and providing higher dimensional accuracy across every part. Built-in smart sensors for material management and print protection automatically detect and alert the user when materials are running low and allows for active jam detection during the entire print duration. Other features such as the Spring Steel build plate, which easily pops out to allow users to queue up their next print, and the 5” full-color capacitive touch screen offers users a highly intuitive and seamless user experience.